|

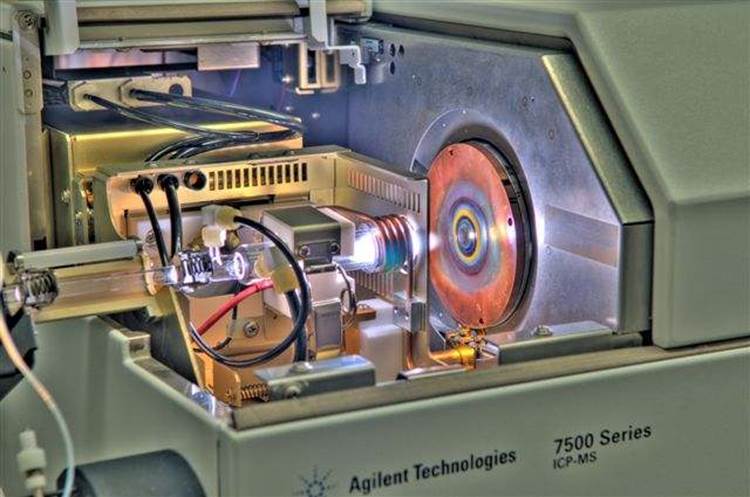

What is ICP-MS?

ICP-MS

is a complex and highly sensitive laboratory instrument that is used to

measure trace metals such as aluminum, copper, lead and mercury in liquid and

solid samples from a diverse range of industries including the environmental,

food, biomedical, chemical, petrochemical, forensic, semiconductor and

nuclear fields. ICP-MS is one of the most advanced analytical instruments in

use – it can detect metals in the sub parts per trillion (PPT) range. Samples are analyzed by ICP-MS typically as

solutions: the sample solution is introduced into a nebulizer, where a stream

of argon gas breaks up the liquid into a fine aerosol and sweeps the smaller

droplets into the central channel of an argon plasma (ICP). The very high

temperature of the ICP (>8000oC) causes the sample droplets to be dried

and dissociated into individual atoms, which are then ionised

before being extracted, through an interface, into a vacuum system. The vacuum system consists of a series of

differentially pumped chambers, the final stage containing the mass

spectrometer and ion detection system. In the vacuum system, electrostatic

lenses keep the ions focused and separate the positively charged ions from

photons and neutral particles. Analyte

ions are separated by the mass spectrometer (MS), which scans rapidly across

the mass range allowing each mass of interest to pass sequentially to the

electron multiplier detector. The

counts measured at the detector are converted to elemental concentration

data. Because of its high performance, complexity and high cost (ICP-MS

instruments cost $180,000 upwards), ICP-MS is very challenging to operate and

labs that have an ICP-MS generally allow only their senior chemists to

operate it. The key to getting the

most from your investment is proper training in operation. Home |

Services | Recruitment | Contact

Us |